Evaporator Design Manual

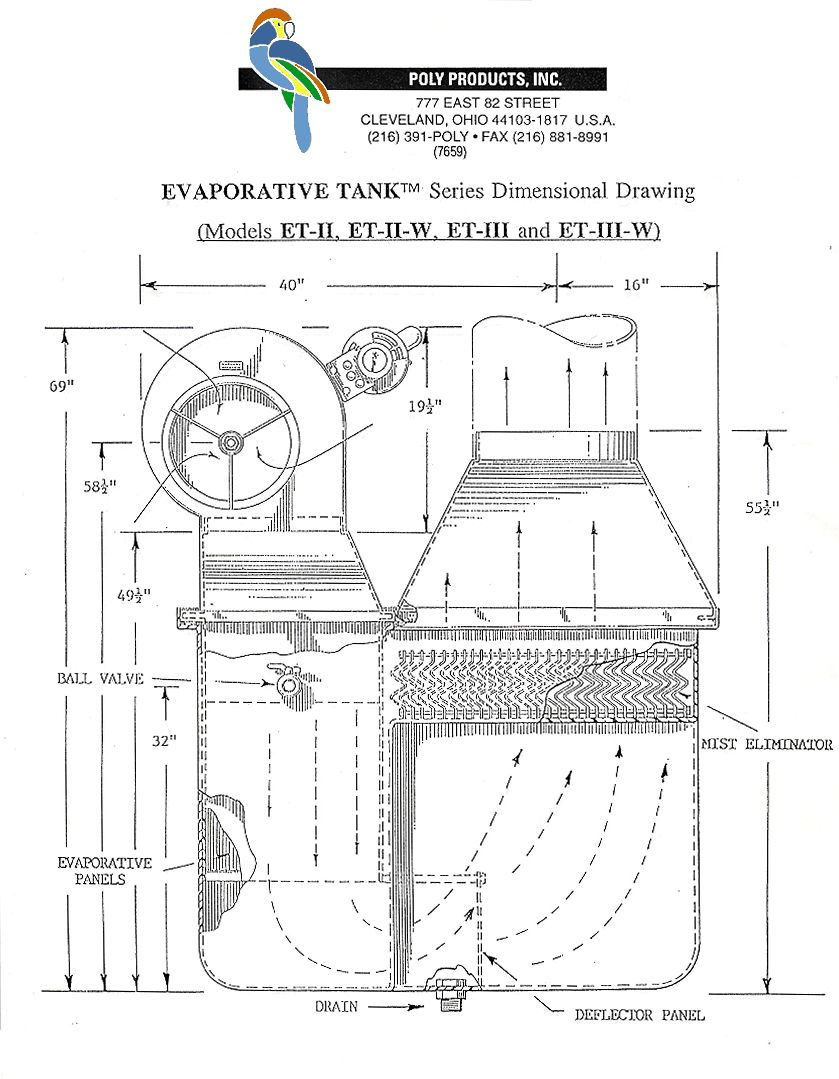

This excellent volume combines a great deal of data only previously available from many different sources into a single, informative volume. It presents evaporation technology as it exists today. Although evaporation is one of the oldest unit operations, it is also an area with dramatic changes in the last quarter century. Although other methods of separation are available, evaporation remains the best process for many applications. All factors must be evaluated in order to select the best evaporator type. This book will be extremely useful in evaluating and deciding which evaporation technology will meet a particular set of requirements.

Making sure your new evaporation system is fully compliant with all regulations is of utmost importance. We can help with regulatory paperwork including air permit exemption paperwork and exemptions for hazardous waste applications. Support For Life You’re not on your own after you purchase an ENCON evaporator. Our Service Engineering Team is here solely to support you, from start-up through the life of the machine. We can provide start-up assistance, either remotely or at the facility. We can also provide comprehensive training. Technical assistance is always available, whether to diagnosis a problem by phone, remote dial-in, UPN connection, or on-site.

Multi Effect Evaporator Design Pdf

Our Engineering team can also provide guidance regarding controls, tanks, valves, pumps, alarms and level sensors for complete wastewater evaporation systems. Documentation support includes ENCON layout diagrams, operational & maintenance manuals, ID diagrams and more.

ENCON even maintains a complete record of all matters having to do with your evaporator, including prior correspondence. This is to ensure continuity is maintained if one of our Service Engineers is traveling or on vacation.

4jh3e manual. Clean up: get the engine room clean: You can use white spirit on a rag, or spcial industrial wipes and/or even paint the bilge with stuff like Danbline so the placve is clean. Exhaust: the exhaust shouldn't leak at all: look for tiniest leak and buy new 76mm exhaust pipe like jfm did for me in Antibes the moment you see anything bad. Engine electrical connections: these connect a bit close to some of the water drain outlets so you can get water dripping on to the loom - use cable ties to tidy the wires up and away. This rubbery exhaust pipe will eventually go manky and rust at the reinforcing so you have to replace aftr a few years - it takes hot fumes and water out of the engine so it's just not gonna last forever.